The Hidden Bottleneck: Why the First 100 Feet Deserve Your Attention

In warehouse operations, efficiency is often measured by throughput, accuracy, and adaptability. Yet there’s a crucial stretch that gets surprisingly little attention: the first 100 feet. This transition zone — from the dock door to internal storage or vice versa — is where products either enter your system or leave it. It’s also where delays frequently begin.

What is the “First 100 Feet”?

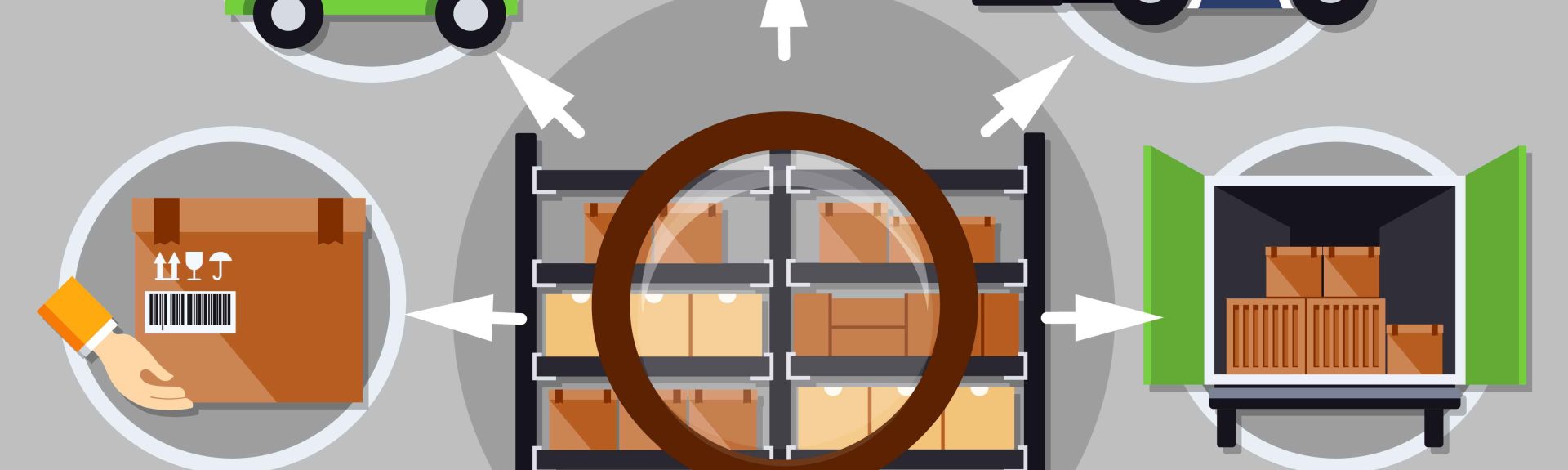

The Transition zone from dock to warehouse flow – or vice versa – where goods first move in or out.

Inbound & Outbound Flow

- Inbound: Truck -> Dock Door -> Unload Zone -> Staging -> Storage Entry

- Outbound: Truck <- Dock Door <- Load Zone <- Staging <- Storage Exit

Why it Matters

- Delays here disrupt the entire facility

- Missed time slots cause costly backups

- Manual handling increases injury risk

Workflow Friction Points

- Dock Door: Unpredictable arrivals and poor visibility into incoming loads

- Staging Area: Overflow or underutilized space slows internal handoff

- Load Zone: Waiting on manual loading creates bottlenecks

- Coordination Gap: Misaligned timing between teams causes stop-and-go flow

Smart Solutions for the First 100 Feet

- Telescopic Conveyors: Speeds up truck loading/unloading while reducing strain and injury.

- Flexible Conveyor Systems: Adapts to space and volume, reducing reliance on forklifts.

- Dock Scheduling Software: Maximizes time slot use and reduces idle truck time.

Why the First 100 Feet Is Often Overlooked

The first 100 feet are deceptively simple in appearance. It’s not a place of high-tech robotics or dense pick zones, but rather a narrow window where products pass through a handoff — from carrier to warehouse, or warehouse to outbound truck. The trouble is that this space often lacks structure, coordination, and investment. When workers rely on manual handling, basic carts, or fixed paths, even small inefficiencies can cause cascading effects throughout the entire operation.

One reason it’s overlooked is that delays that originate here often manifest elsewhere. A truck is waiting at a crowded dock. A backed-up staging area. A sudden shortage of available labor. It’s easy to blame downstream processes, but when the transition zone is clogged or inconsistent, everything that follows suffers.

What complicates matters further is the unpredictability of real-world logistics. Weather, driver availability, fluctuating order volumes — all of these variables hit the dock doors first. If your first 100 feet can’t flex with these changes, delays ripple into picking, packing, and shipping areas.

Building Resilience Where Flow Begins

The key to optimizing the first 100 feet lies in rethinking how flow, safety, and adaptability interact. Warehouses need this zone to be fast, but not rushed. Flexible, but not chaotic. The right equipment and layout don’t just speed up movement; they reduce risk and create predictability.

For example, facilities that invest in smart conveyor configurations are better able to accommodate peak periods without overwhelming dock staff or staging areas. Tools like modular conveyors not only improve ergonomics and reduce fatigue but also shorten dwell times, allowing carriers to stay on schedule and improving overall dock utilization.

Equally important is the coordination between transportation and floor teams. Visibility tools like dock scheduling software help orchestrate flow in real time, allowing teams to respond to shifting volumes without scrambling. When trucks, docks, and storage zones all speak the same operational language, everything moves with more certainty and less friction.

At the end of the day, the first 100 feet is more than just a passageway. It’s the starting line for productivity.

Read Also:

- What are PLG Supplies? A Complete Guide to Product-Led Growth in Supply Chains

- Where Particles Hide In Production Environments: Beyond The Obvious Risks

- Avoiding Production Setbacks: Why Strong Network Infrastructure Is Vital in Today’s Smart Factories

- The Future of Supply Chain Management in Businesses